Ornamental paneling with secure stained glass.

with secure

stained glass.

DAFERMANN (Private Limited Company) started its activity in 1994 and in 2001 it began importing and distributing window glass and mirror.

The activity of the firm has constantly grown, from 1-2 lorries a month (10 a year) to over 1100 at the moment, placing the firm on the first place among window glass distributors in Romania.

The DAFERMANN team, made up of 60 specialists and consultants, is here to offer you information and suggestions so that you can make the best decisions, having in our company a trustworthy and reliable partner.

Our sales representatives cover all the regions of the country.

–

We have 15.000 square metres of storage space in Bacau- our central warehouse and over 5000 square metres in other locations across the country (in Zalau, Timisoara, Deva, Valenii de Munte-Prahova).

The fleet consists of 18 trucks, with or without a trailer, all equipped with advanced cranes and 8 utility vehicles specialised in transporting glass sheets.

We permanently have in stock a wide range of glass and mirror (more than 150 types) of different thickness and sizes, such as: clear float, extra clear, anti-reflected, fire resistant, low-e (soft and hard), solar control, reflected, body-tinted, patterned, decorative, laminated glass, and also a varied range of clear and tinted mirrors. Since 2012 we sell a varied range of window storage systems (sheets, cases, jumbo) and transport systems for heat insulating glass.

Consulting / 60 specialists

Warehouse / 21000 mp

Products / 200 sizes

Transport / 20 equipped trucks

A glass universe is opening in front of you!

We permanently have in stock a wide range of float, patterned, decorative glass, of different types and sizes, and also a wide variety of clear and tinted mirrors. Our products can be used by joinery and furniture distributors and producers, builders, architects, those who are passionate about art or hardware, professionals or amateurs.

“Float“ is a term used for perfectly flat-shaped, transparent glass (the main product). The term “float” glass comes from the production method, introduced in Great Britain by Sir Alastair Pilkington at the end of the year 1950, a method that is used for over 90% of the float glass produced nowadays.

Production: the basic materials (silicon sand, calcium, oxide, soda and magnesium) are well balanced and mixed together, then introduced into a furnace where they are melted at 1500° C. Afterwards the melted glass pours from the glass-furnace into a melted tin pot like a flowing strip.

The glass, which is extremely thick, and the tin, which is very fluid, don`t mix together, the contact surface between these two materials being perfectly flat. When the glass leaves the melted tin pot it is cold enough to go through an annealing chamber called leer. Here it cools off at controlled temperatures until it reaches the room temperature.

Thicknesses and sizes available

| 2 mm | 1830 x 1220 mm |

| 3 mm | 3210 x 2250 mm, 1830 x 2440 mm, 2250 x 1605 mm |

| 4 mm | 3210 x 2250 mm, 1830 x 2440 mm, 2250 x 1605 mm |

| 5 mm | 3210 x 2250 mm, 2250 x 1605 mm |

| 6 mm | 3210 x 2250 mm, 1830 x 2440 mm, 2250 x 1605 mm |

| 8 mm | 3210 x 2250 mm,1830 x 2440 mm, 2250 x 1605 mm |

| 10 mm | 3210 x 2250 mm,1830 x 2440 mm, 2250 x 1605 mm |

Ultra clear float glass is float glass with a special transparency.

It is perfectly translucent, there is no colour shade in its mass compared to the clear float glass that has a greenish shade.

Thicknesses and sizes available

| 4 mm | 3210 x 2250 mm, 2250 x 1605 mm |

| 6 mm | 3210 x 2250 mm, 2250 x 1605 mm |

| 8 mm | 3210 x 2250 mm, 2250 x 1605 mm |

| 10 mm | 3210 x 2250 mm, 2250 x 1605 mm |

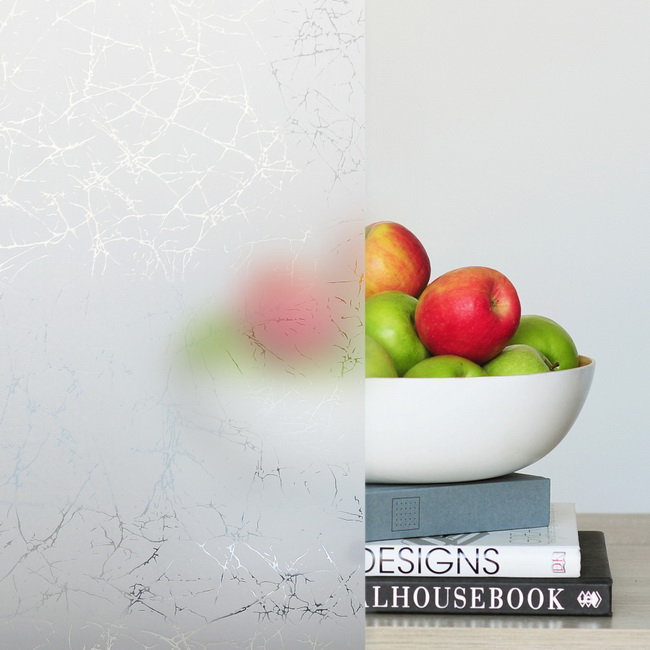

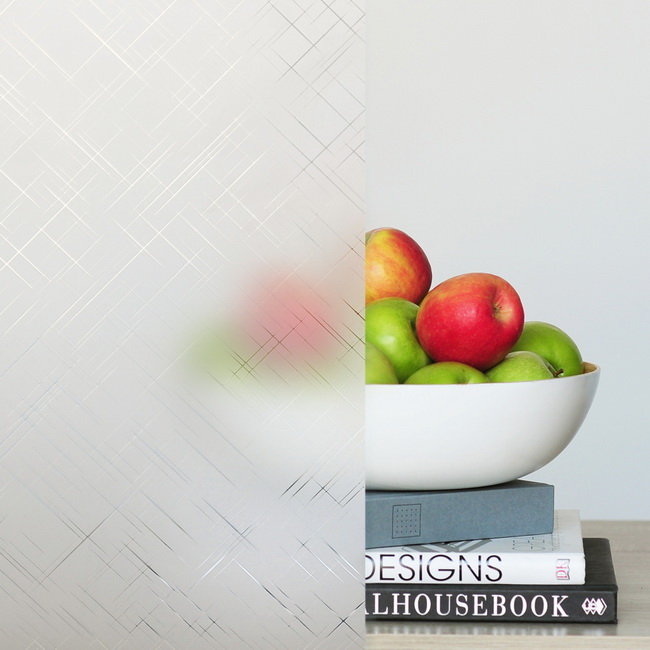

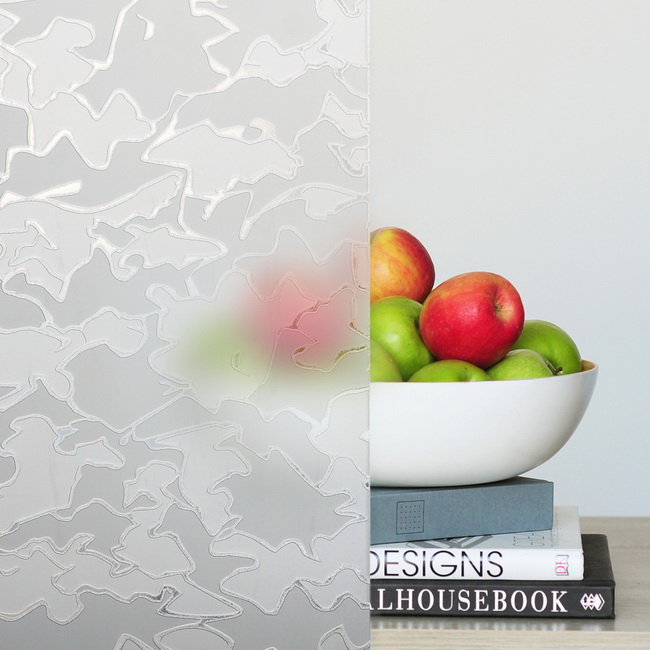

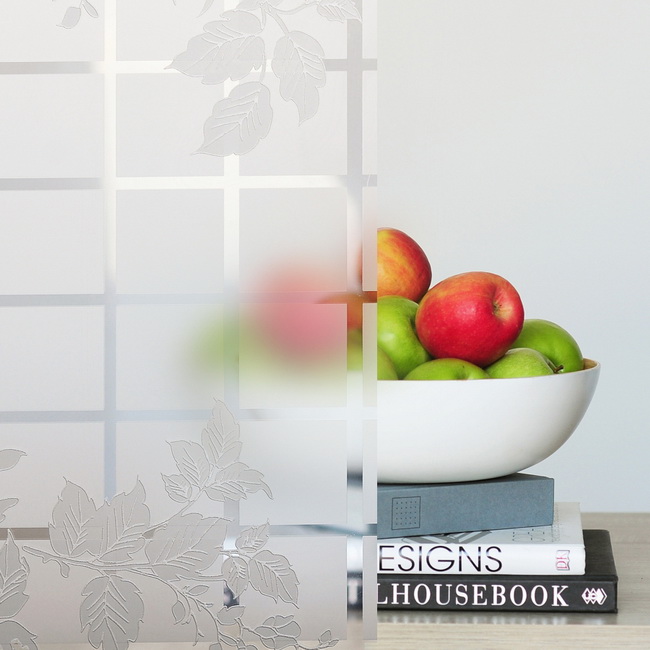

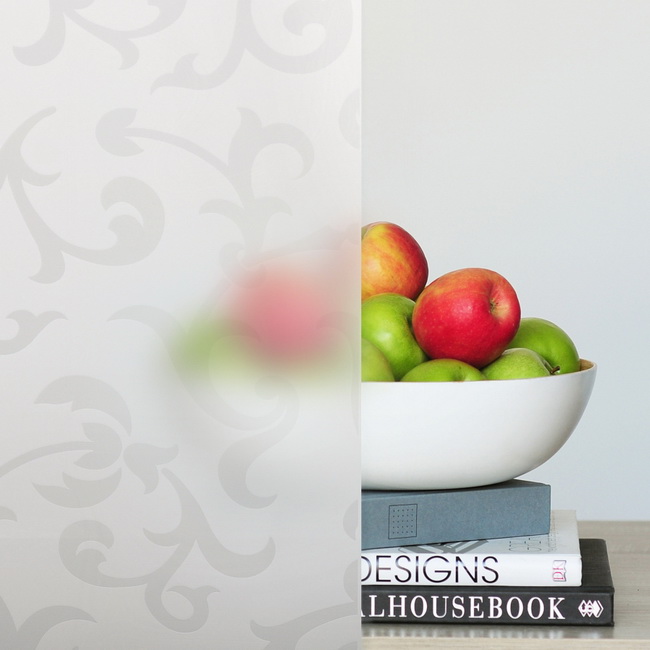

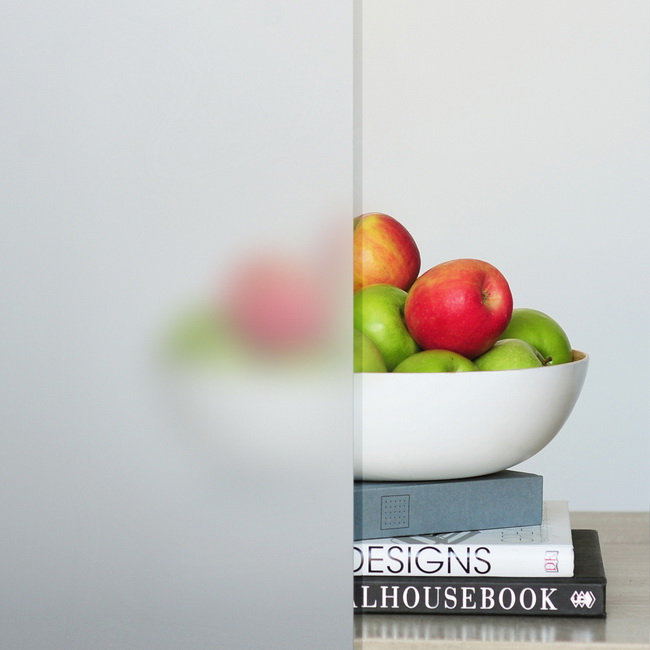

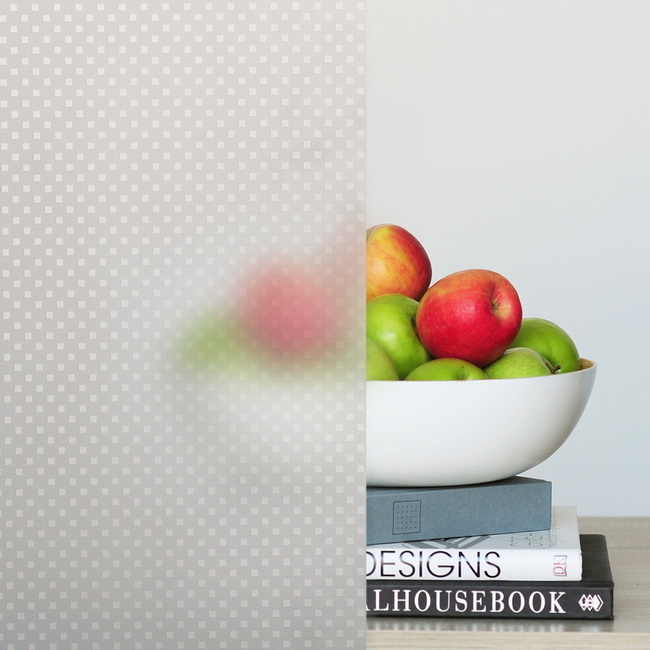

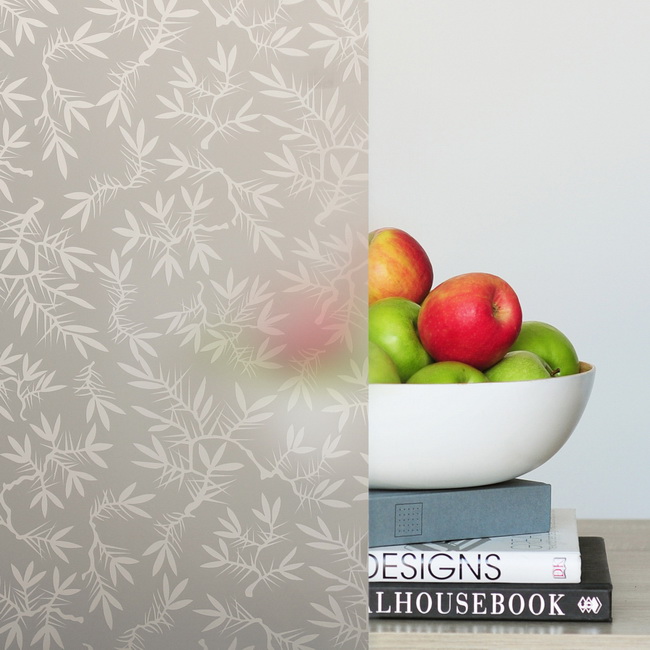

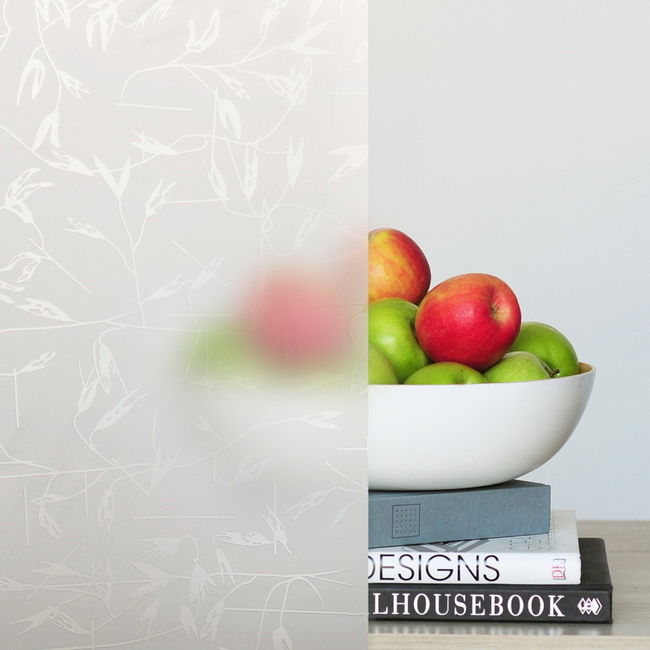

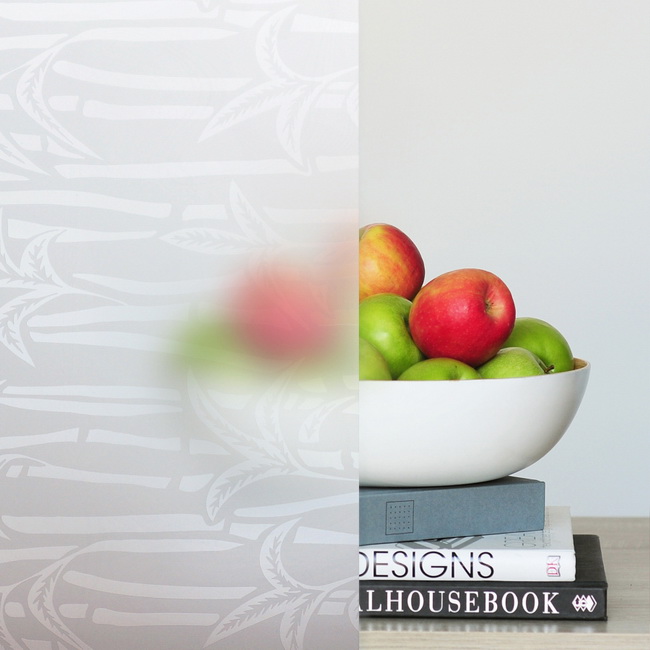

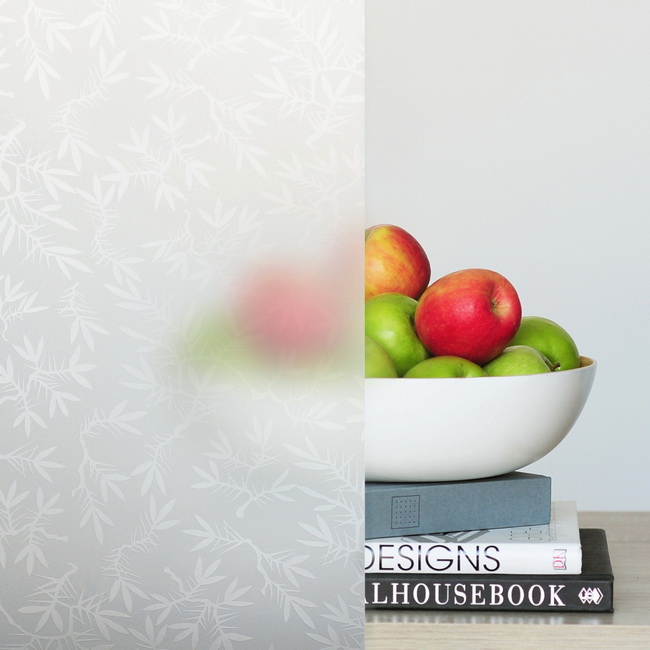

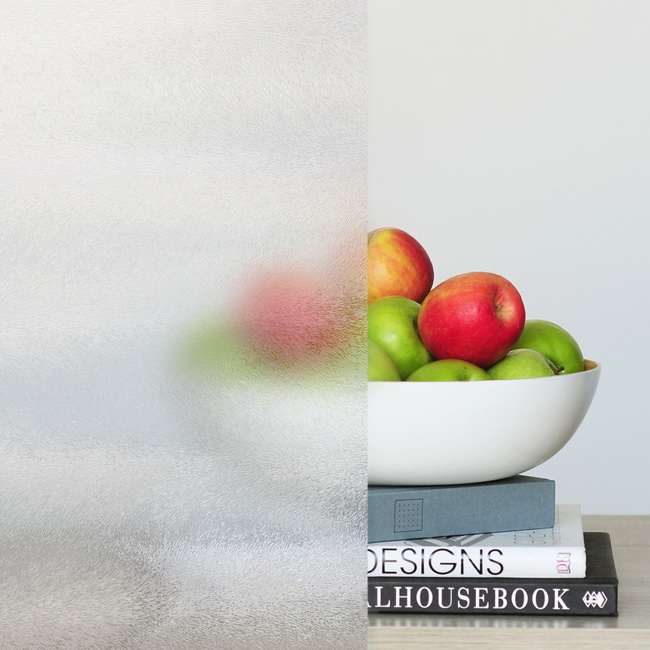

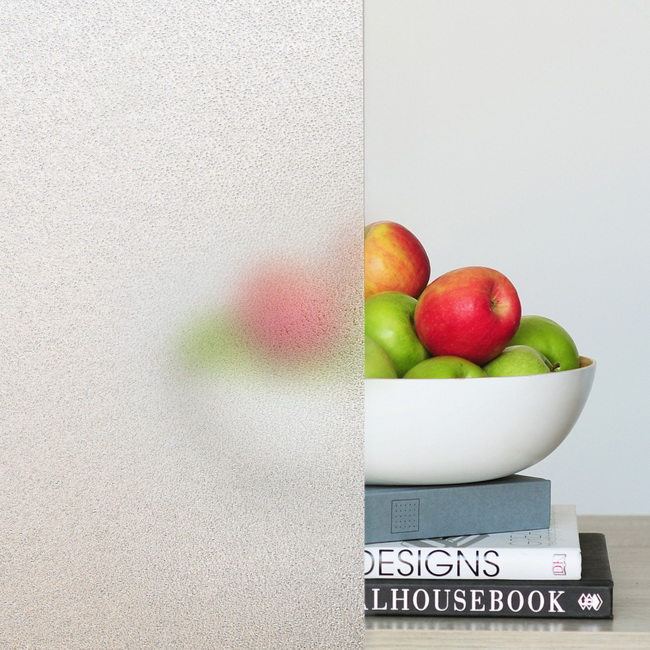

Decorative glass is obtained through acid corrosion/etching of one side of the float glass. This type of glass has a distinct, smooth, uniform aspect - satiny like, the light that goes through it having a diffuse effect.

This type of glass can be used for doors, showers, furniture, walls, etc.

We offer two types of decorative glass produced by Henghao-China and Ayna-Turkey.

Thicknesses and sizes available

| 4 mm | 3300 x 2134 mm, 2250 x 1650 mm, 2440 x 1830 mm |

| 8 mm | 3300 x 2134 mm, 2250 x 1650 mm, 2440 x 1830 mm |

| 10 mm | 3300 x 2134 mm, 2250 x 1650 mm |

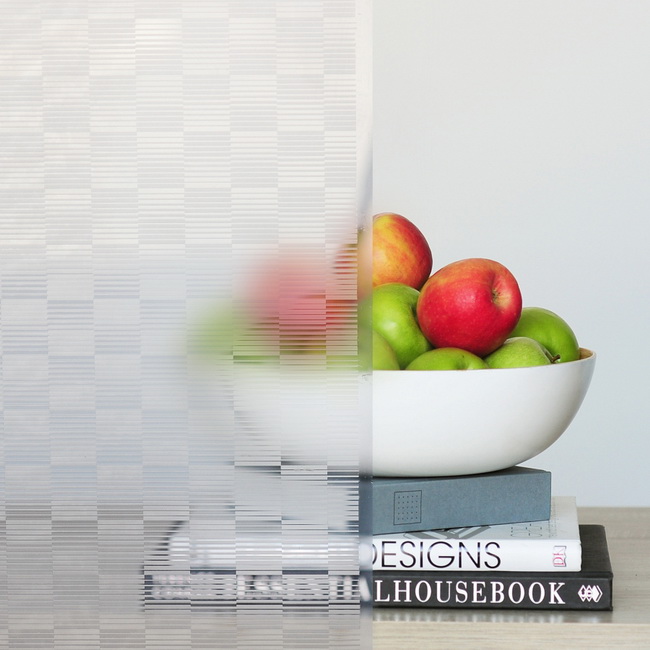

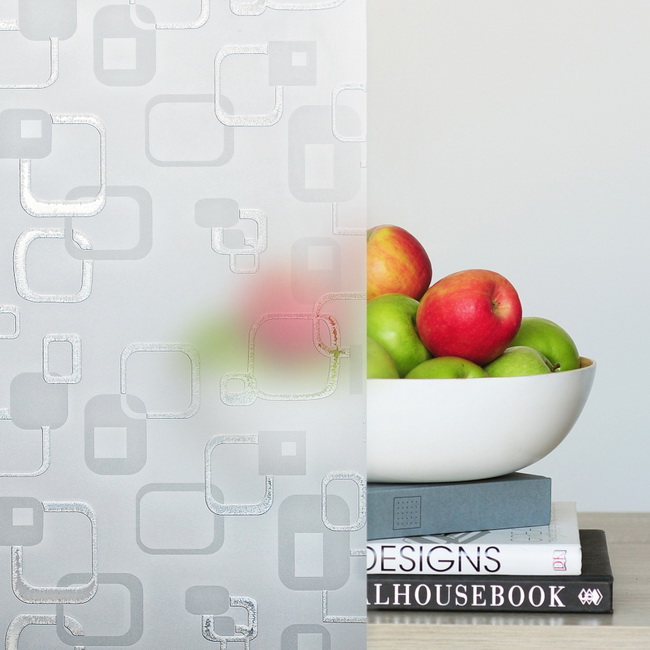

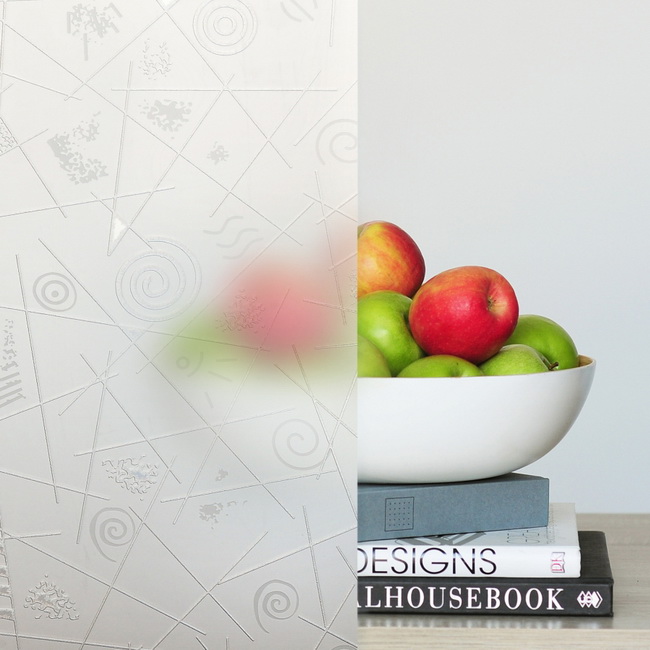

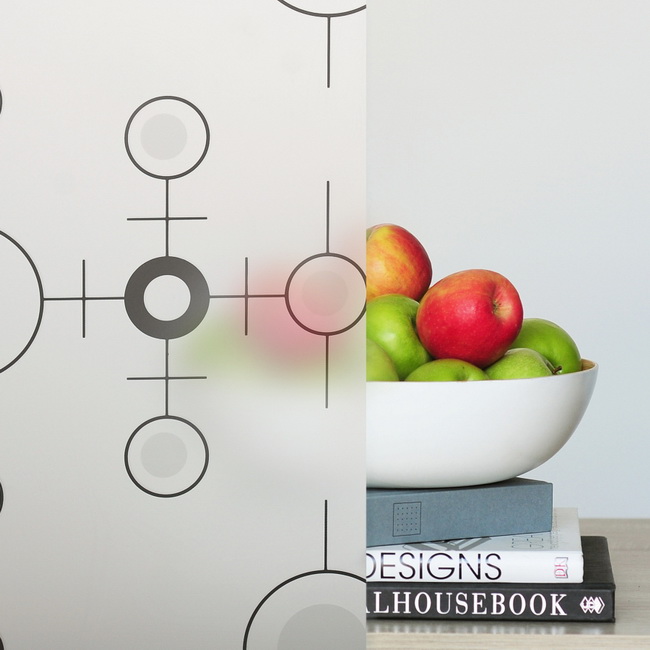

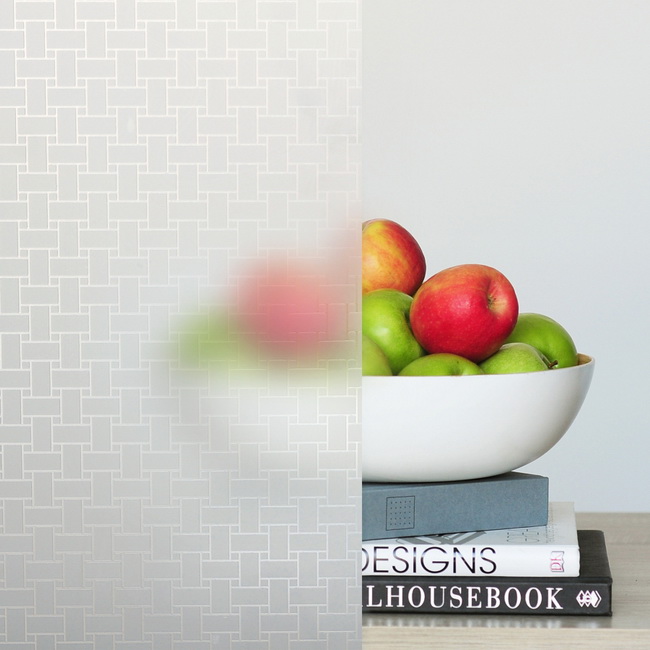

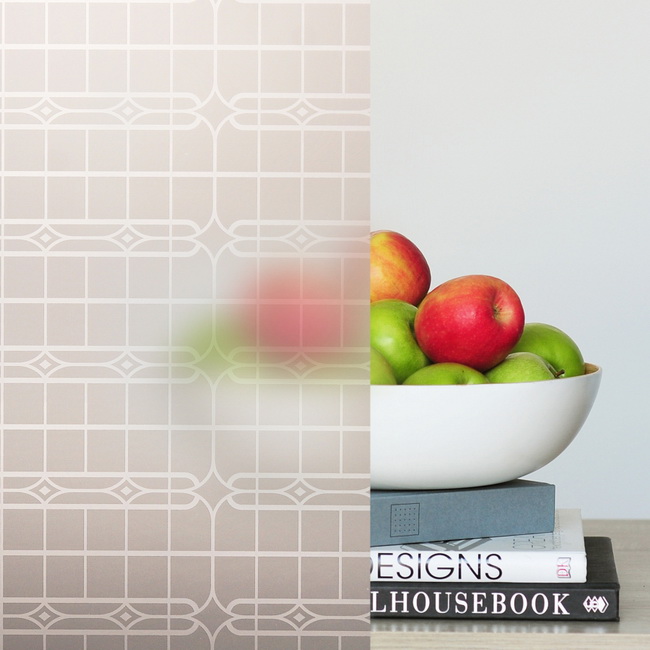

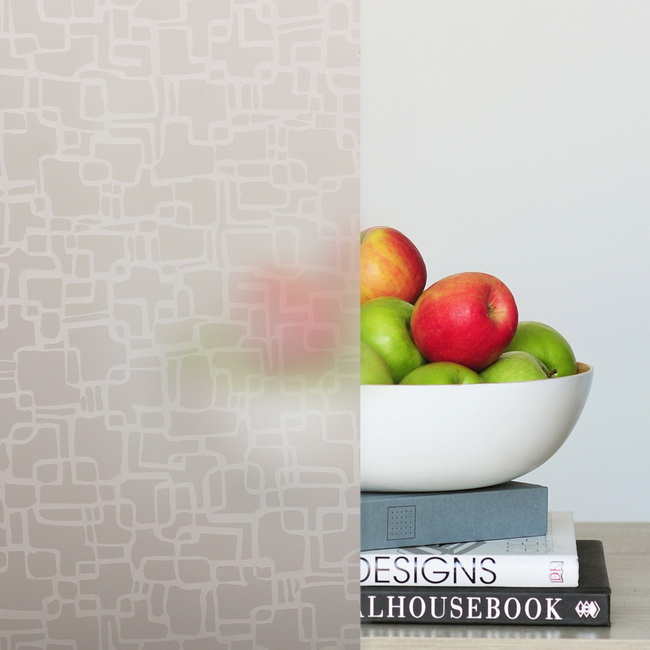

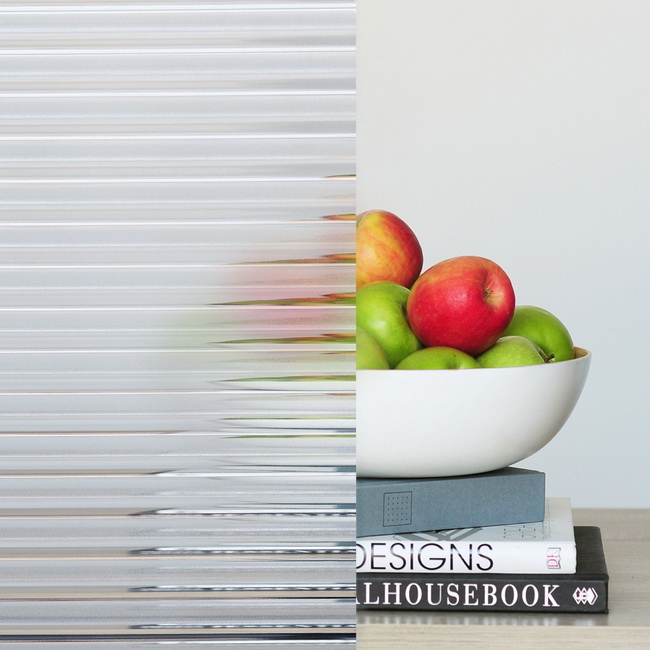

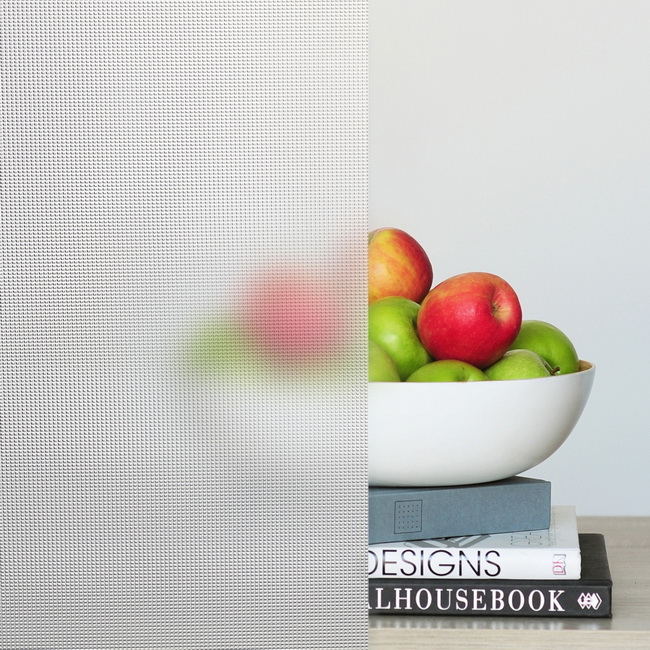

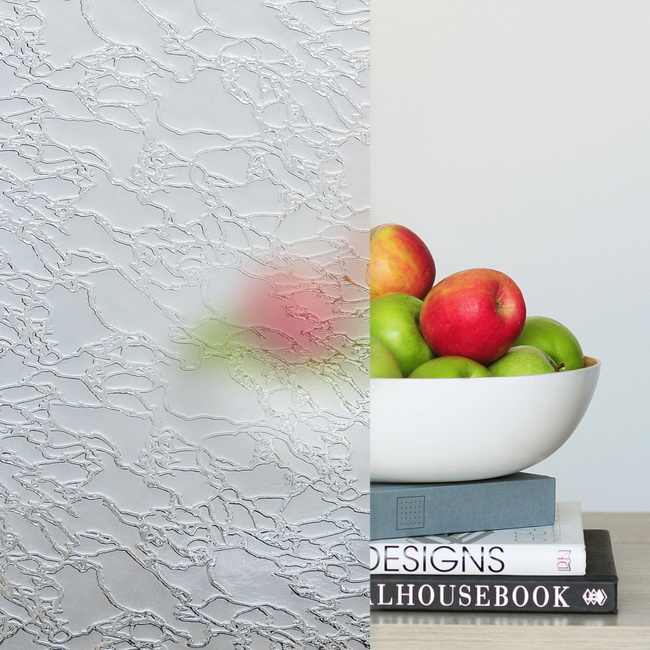

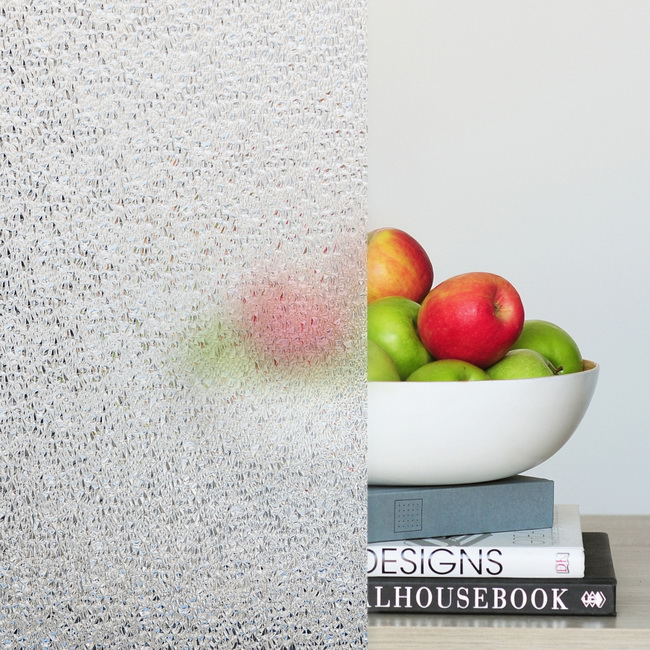

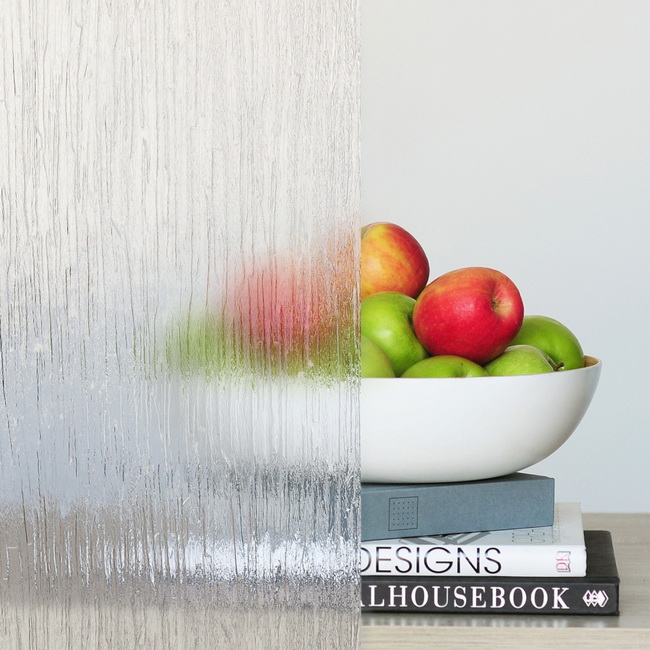

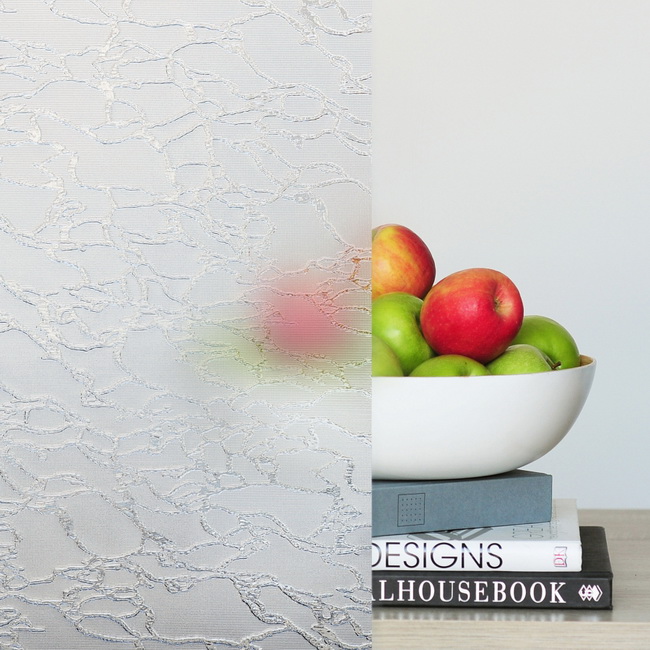

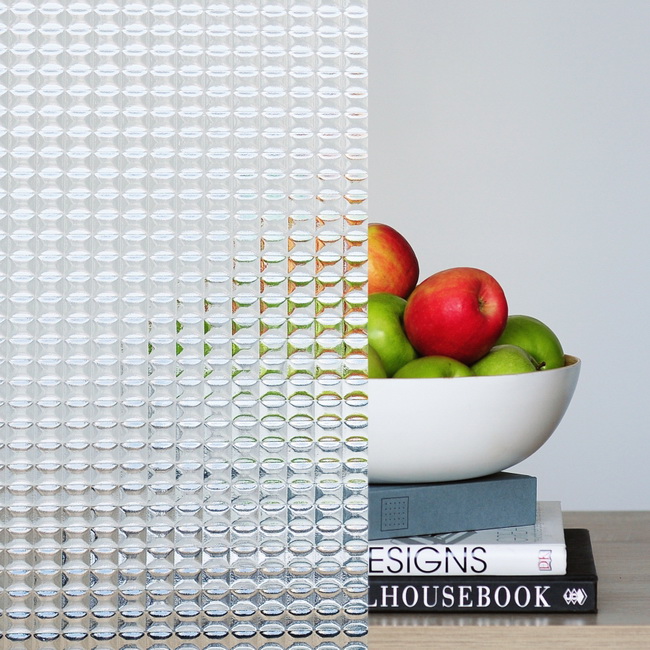

Patterned glass is clear or tinted glass, that has a different structure on both sides of the sheet. One of the sides is perfectly smooth, the other side has patterns of varied complexity impressed on it.

The depth, the thickness and the shape of the printed patterns greatly determine the degrees and directions of the light distribution, through specific phenomena of reflection and refraction.

This type of glass can cover a wide range of applications, such as: interior design and decorations, furniture, windows.

Production: the glass is obtained as a result of a technological process of rolling. The semi-melted glass goes through two metallic rolls, the distance between the rolls determines the thickness of the sheet. The bottom roll is engraved with the negative of the printed pattern.

Thicknesses and sizes available

| 4 mm | 2440 x 1830 , 2440 x 1524 , 2134 x 1524,2000 x1500mm |

Low-E glass is clear float glass, with a microscopic coating of metal oxide which allows the heat and the solar light inside, at the same time blocking the transfer of heat outside and reducing heat loss considerably during the cold season.

The pyrolitic production (On- Line) Low-E HARD: the clear float glass is covered in a coating of metal oxide applied pyrolitically when it leaves the tin bath (at 650°C). As a result the cover is very resistant to mechanical deterioration, and this type of Low-E glass can be cut, secured, laminated the same as normal glass with no coating.

The magnetronic production (Off- Line) Low-E SOFT: clear float glass gets, on one of its faces, a silver applied coating-magnetronic coating. Acest tip de Low-E trebuie sa fie utilizat exclusiv in geamul termoizolan cu pelicula in interior. Poate fi securizat si laminat.

Thicknesses and sizes available

| 4 mm | 3210 x 2250 mm |

| 6 mm | 3210 x 2250 mm |

Solar control glass is clear float glass which in addition to the Low-E features (reduces the loss of heat during the cold season), provides an enhanced comfort during the summer by rejecting the solar energy, without the need of an additional solar protection. This means an ideal room temperature at low electricity costs for cooling.

Thicknesses and sizes available

| 4 mm | 3210 x 2250 mm |

| 6 mm | 3210 x 2250 mm |

It`s float glass obtained by adding some chemical colouring agents in the melted glass mass and then floated.

The colour, according to the intensity of the colouring agent added, ensures an enhanced absorption of ultraviolet rays into the glass mass, thus reducing the outside heat exchange.

The colour is also the attribute that recommends this type of glass, not only as an important architectural element in emphasizing the exterior aspect of facades, but also for toning some interior design elements: doors, screens, stair panels, etc.

The most frequently added agents and the colours they produce are:

| Iron | Green, Brown, Blue |

| Manganese | Violet |

| Chrome | Green, Blue, Pink |

| Vanadium | Green, Blue, Grey |

| Copper | Blue, Green, Red |

| Cobalt | Blue, Green, Pink |

| Nickel | Yellow, Violet |

| Cadmium yellow | Yellow |

| Titanium | Violet, Brown |

| Cerium | Yellow |

| Carbon sulfide | Amber, Brown |

| Selenium | Pink, Red |

| Gold | Red |

Thicknesses and sizes available

| 4 mm | 3300 x 2134 mm, 3210 x 2250 mm |

| 6 mm | 3300 x 2134 mm, 3210 x 2250 mm |

| 8 mm | 3300 x 2134 mm, 3210 x 2250 mm |

| 10 mm | 3300 x 2134 mm, 3210 x 2250 mm |

Regular float glass becomes, in this case, a frame for the coating of a metallic oxide film. Placing the reflected glass in the heat insulating package with the side that has no coating outwards creates, through the reflection of the solar radiations, the mirroring effect, preventing day visibility inside buildings that are equipped with this type of glass.

The coating of body-tinted float glass reduces considerably the exterior heat exchange, by raising both the absorption degree and the high reflection degree of solar radiations due to the mirroring effect. It is the main reason why this type of glass is most frequently used in covering facades.

The pyrolitic production (On-Line): in this process the metallic oxides are applied directly onto the glass surface during the floating process (while the glass is still hot in the annealing space).

The magnetronic production (Off-Line): in this type of process one or more layers of metal oxide are applied under vacuum onto the glass surface previously heated. The film applied through this technique is soft and must be protected against external influences. Therefore this type of glass is placed in the heat insulating package with the film on the inside.

Available RANGES: BRONZE, CLEAR, GREEN, BLUE, GREY

The reflected glass traded by our firm is available in two versions: ECONOMIC - RIDER CHINA (bronze, green, blue) and TOP QUALITY - PPG USA (bronze, clear, grey), which represent a range of classical reflected glass that can be easily curved and secured.

Thicknesses and sizes available

| 4 mm | 3300 x 2134 mm, 3210 x 2250 mm |

| 6 mm | 3300 x 2134 mm, 3210 x 2250 mm |

Anti-reflected glass is clear float glass, with a special coating applied which reflects light remotely. This type of glass offers a maximum of transparency and clarity and does not allow the forming of the reflection effect when a source of light reflects onto the surface of the window.

The clarity of the anti-reflected glass makes it appropriate for all the applications in which transparency has to be the highest.

Interior: paintings, framing of high quality image, etc.

Thicknesses and sizes available

| 2 mm | 1830 x 1325 mm |

Laminated glass is a combination of two or more sheets of glass, having one or more intermediate layers of plastic material (PVB or EVA). In case of breakage, the intermediate layer holds the pieces together and continues to ensure a resistance to the passage of people or objects.

This type of glass is appropriate for spaces where it is important to ensure a resistance after the breaking, such as: stores, balconies, railings, glass stairs.

Production: it is obtained by gluing two sheets of glass to one or more layers of PVB under the action of heat and pressure.

Thicknesses and sizes available

| 3.3.1 | 3210 x 2250 mm |

| 3.3.2 | 3210 x 2250 mm |

| 4.4.1 | 3210 x 2250 mm |

| 4.4.2 | 3210 x 2250 mm |

| 5.5.1 | 3210 x 2250 mm |

| 5.5.2 | 3210 x 2250 mm |

Fire-resistant glass can be classified in two categories:

Fire-resistant glass - heat transmitting glass: contains flames and inflammable gas for a short period of time, but does not prevent the transmission of heat to the other side of the glazing. (example: wired glass, reinforced laminated glass).

Fire-resistant glass - fire-insulating glass: contains flames and inflammable gas for a longer period of time and prevents not only the transmission of flames and smoke but also of heat to the other side of glazing.

Mirrors are obtained by coating one of the glass surfaces with a metallic reflective layer, protected by a thin layer of copper for protection against oxidation.

In addition, a layer of paint that ensures not only a mechanical protection of the oxide layer, but also an extra protection against oxidation, is added at the end of the process. Except for the clear version, mirrors are produced in different tones of colours: bronze, blue, green or grey.

Thicknesses and sizes available

| 3 mm | 3210 x 2250, 1830 x 2440, 2250 x 1605 mm |

| 4 mm | 3210 x 2250, 1830 x 2440, 2250 x 1605 mm |

Dafermann`s attributes are advanced technology, reliability and aesthetics and based on them we work closely with the most important distributors in the world: SISECAM Turkey, PPG United States, CAIRO GLASS Egypt, HENGHAO China, SAINT GOBAIN Romania, in order to offer you quality and comfort.

Easier than you would have thought! If you want to be our partner contact us. Here at Dafermann you can find all the glass storage systems: separators and racks for transport.

Dafermann SRL

Str. Constantin Musat nr. 3, 600092

Bacau - Romania

Telefon/Fax: +4 0234 571 666